Cell Phones, Sporting Goods, and Soon, Cars: Ford Innovates with “Miracle†Material, Powerful Graphene for Vehicle Parts

November 23rd, 2018 Bangkok – It’s in cell phones and even some sporting goods – and soon, for the first time in automotive, it will be under the hood in Ford vehicles. Ford Motor Company is announcing the use of graphene – a two-dimensional nanomaterial – in vehicle parts.

Graphene has recently generated the enthusiasm and excitement in the automotive industry for paint, polymer and battery applications.

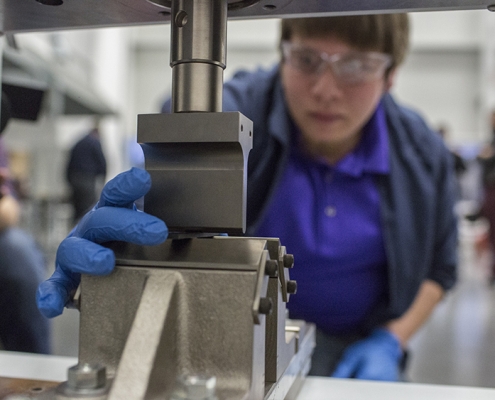

Dubbed a œmiracle material by some engineers, graphene is 200 times stronger than steel and one of the most conductive materials in the world. It is a great sound barrier and is extremely thin and flexible. Graphene is not economically viable for all applications, but Ford, in collaboration with Eagle Industries and XG Sciences, has found a way to use small amounts in fuel rail covers, pump covers and front engine covers to maximize its benefits.

œThe breakthrough here is not in the material, but in how we are using it, said Debbie Mielewski, Ford senior technical leader, sustainability and emerging materials. œWe are able to use a very small amount, less than a half percent, to help us achieve significant enhancements in durability, sound resistance and weight reduction – applications that others have not focused on.

Graphene was first isolated in 2004, but application breakthroughs are relatively new. The first experiment to isolate graphene was done by using pencil lead, which contains graphite, and a piece of tape, using the tape to pull off layers of graphite to create a material that is a single layer thick – graphene. This experiment won a Nobel Prize in 2010.

In 2014, Ford began working with suppliers to study the material and how to use it in running trials with auto parts such as fuel rail covers, pump covers and front engine covers. Generally, attempting to reduce noise inside vehicle cabins means adding more material and weight, but with graphene, it’s the opposite.

œA small amount of graphene goes a long way, and in this case, it has a significant effect on sound absorption qualities, said John Bull, president of Eagle Industries.

The graphene is mixed with foam constituents, and tests done by Ford and suppliers has shown about a 17 percent reduction in noise, a 20 percent improvement in mechanical properties and a 30 percent improvement in heat endurance properties, compared with that of the foam used without graphene.

œWe are excited about the performance benefits our products are able to provide to Ford and Eagle Industries, said Philip Rose, XG Sciences’ chief executive officer. œWorking with early adopters such as Ford Motor Company demonstrates the potential for graphene in multiple applications, and we look forward to extending our collaboration into other materials and enabling further performance improvements.

Over the past several years, Ford has tested and developed additional œmiracle materials to improve the design, performance and environmental impact of vehicles across Asia Pacific. One such material is high-quality nylon fiber from carpet and garment factories. The team uses it to make the cooling fan blade found inside the Ford Focus and Escort. By working with suppliers to tap into this excess nylon fiber (or yarn), which typically makes up around 1-3 percent of all yarn used in some factories, Ford saves over 700,000 kilometers of yarn from landfills every year in Asia Pacific – nearly enough to travel to the moon and back.

Ford also uses carefully selected, durable parts from washing machines to make air deflectors, which sit just under a vehicle’s floor and reduce air drag force and improve fuel efficiency, ultimately saving drivers money. And Ford uses seat fabrics with REPREVE-branded fiber, which is made from 100 percent recycled materials, including plastic bottles. Testing continues on other strong and sustainable materials, such as bamboo, which can rival or even better some types of metal.

Graphene is expected to go into production by year end, used in parts on the Ford F-150 and Mustang and eventually, other Ford vehicles.